- You have no items in your shopping cart

- Continue Shopping

Description

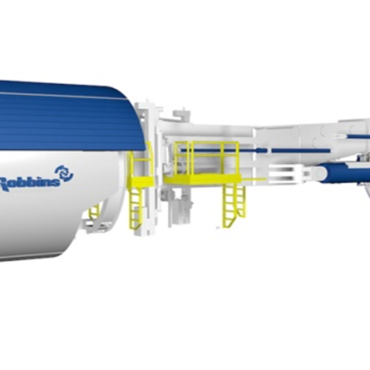

Crossover TBM: Crossover TBMs are machine designs that feature advantages from two different types of TBMs, and can “cross over” between widely varying ground types that would normally require multiple machines. They are also known as hybrid or dual mode machines in the tunneling industry.

Standing for a Crossover (X) between Rock (R) and EPB (E), the XRE has been designed and deployed by Robbins on multiple projects that feature sections of both hard rock and soft ground in the tunnel alignment. Using features of both EPB and Single Shield Hard Rock machines, the XRE has successfully been used on mixed ground projects in Australia, Turkey, Mexico, India, and more.

At diameters over 12 m, the XRE design becomes even more versatile. Large XRE TBMs can be designed without compromising one machine type over the other.

CROSSOVER SLURRY/EPB (XSE) TBM

In urban environments with mixed ground conditions, settlement is not an option, and must be kept as close to zero as possible. The XSE TBM—standing for a Crossover (X) between Slurry (S) and EPB (E), fits the bill in many cases. In variable ground the XSE combines the best aspects of both proven TBM designs, making for an incredibly versatile solution.

- Vertical conveyor: Robbins’ vertical conveyors can bring the rock up a shaft to the surface. Whether your tunnel is 20 m or 200 m deep, Robbins vertical conveyors will reliably deliver the rock to the surface with minimal spillage. Robbins custom designs each vertical conveyor specifically to suit the project.

Robbins has two vertical conveyor designs: the traditional “S” type and our new “J” type. For a deep shaft application, use our steel cord belt “S” type conveyors. However, if you have a small diameter shaft of moderate depth, our “J” type conveyor may be the economical solution you’ve been looking for. The Robbins “J” type vertical conveyor has an innovative design.

Details will provide upon request.